CVT technology and eCVT technology differ greatly.

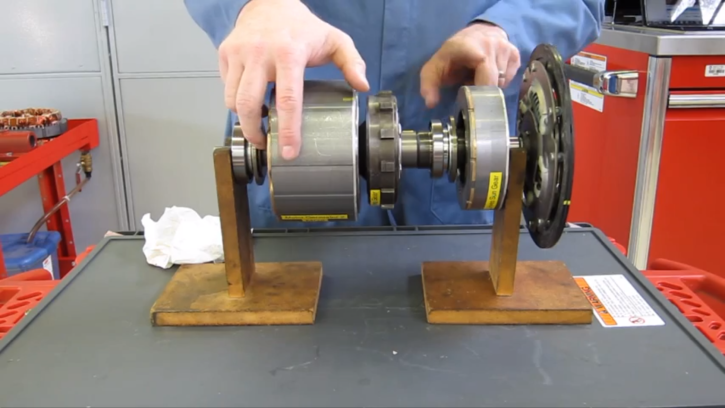

A variation of a standard automatic transmission, Toyota CVT transmissions employ an innovative design that really does not use standard gears. Rather than have specified gears like a standard six-speed automatic, a continuously variable transmission possesses what can best be described as a single and variable “universal” gear. If you've been shopping for a new car recently, you've undoubtedly found that large numbers of late-model vehicles are equipped with a continuously variable automatic transmission (CVT). A comparison and demonstration of the 2nd and 3rd generation Toyota hybrid transaxlesTIMELINE:0:00 Introduction0:51 Components from the 1st, 2nd, and 3rd gen.

The basic mechanisms of each are completely dissimilar.

You may have noticed that AMSOIL Fuel Efficient Synthetic (ATL) and Multi-Vehicle Synthetic ATF (ATF) are now recommended for electronically controlled continuously variable transmissions (eCVTs) in certain vehicles. eCVTs, such as those found on the Toyota Prius, are significantly different from belt- and chain-driven continuously variable transmissions (CVTs). Several automakers use CVT technology, so it’s important to understand the differences between belt-and chain-driven CVTs and eCVTs, which are closer to traditional step-type automatic transmissions in design.

“Instead, an eCVT uses electric motor/ generators to control the speeds of planetary gearset components. This allows the eCVT to continuously change the gear ratio, keeping the engine’s rpm in the sweet spot.”

Your Transmission's Primary Purpose

The primary purpose of any transmission, regardless of type, is to transfer power from the engine through the drivetrain and, finally, to the wheels. To do so, it must work within a narrow engine rpm band to ensure it produces enough torque for the immediate needs of the vehicle and then transmit that torque to the driveline. Getting a heavy vehicle moving from a dead stop requires a lot of torque. Step-type automatic transmissions use a set of gears called planetary gears that work together in different combinations called gear ratios. These gear ratios make it possible to get a vehicle moving from a dead stop and continue a smooth pattern of acceleration all the way up to cruising speed. Each “step” is simply the transmission changing from one gear ratio – or one speed – to the next.

Traditional automatic transmissions select a low gear ratio to get the vehicle moving from a dead stop. As the vehicle builds momentum, less torque is required to keep it moving and the transmission shifts to higher gear ratios in sequence, slowing the engine at each step until the vehicle is at cruise. Traditional automatic transmissions have been in use for over half a century. The efficiency of this technology has been enhanced over the years, but there is always room for improvement.

_03.jpg/220px-Toyota_electronic_continuously_variable_transmission_(2010-10-16)_03.jpg)

The Inefficiency of Conventional Transmissions

With ever-rising fuel economy standards, auto manufacturers spend a lot of time looking at ways to use the transmission to improve the engine’s efficiency. Each engine design produces its most efficient power at a predetermined rpm – the “sweet spot.” One key to better fuel efficiency is keeping the engine in its sweet spot for as long as possible.

When you drive a conventional steptype automatic transmission, you feel the rpm rise and drop each time the transmission shifts to the next gear ratio. Each one of these bumps is an inefficiency that consumes extra fuel because the engine is taken out of its sweet spot. The same is true when you’re climbing a grade and the transmission drops into a lower gear, making the engine run faster and use more fuel. One way manufacturers address this issue is by adding more gear ratios. This has the benefit of shortening the duration of the bumps and gives the transmission more options to keep the engine at its optimum rpm. The inefficiencies can’t be completely eliminated, however, because the transmission is physically limited by a finite number of gear ratios.

How Transmissions Are Changing

CVTs take a different approach to managing rpm. Instead of gears, the most common CVTs use a metal belt or chain running between two pulleys. These pulleys are designed to spread open or squeeze closed under hydraulic pressure, forcing the belt or chain to ride higher or lower in them. The advantage of this system is the vehicle’s computer can quickly and continuously adjust the pulleys to whatever ratio is required for peak efficiency because it isn’t physically limited by gears. When driving a CVT-equipped vehicle the driver pushes on the gas pedal and the CVT adjusts to keep the engine at its most efficient rpm through the entire acceleration process. There are no bumps or rpm increases felt by the driver. This is even true when climbing a grade. The engine stays at its most efficient rpm and the CVT adjusts to allow the car to get over the hill.

The eCVT found on the Toyota Prius and other hybrids differs from CVTs found in other vehicles, such as the 2013 Nissan Altima or 2012 Scion iQ, because it does not use a belt or chain connected to a pair of variable pulleys. Instead, an eCVT uses electric motor/ generators to control the speeds of planetary gearset components. This allows the eCVT to continuously change the gear ratio, keeping the engine’s rpm in the sweet spot. Just like when driving other CVT-equipped vehicles, drivers of vehicles with eCVTs don’t feel the step change common to traditional automatic transmissions, yet the mechanisms (planetary gears) to achieve acceleration are largely the same.

Premium Protection for Your eCVT Transmission

Ecvt Transmission Problems On Rx 450h Lexus

Recent test data has shown we can confidently recommend AMSOIL Fuel Efficient Synthetic Automatic Transmission Fluid and AMSOIL Multi-Vehicle Synthetic Automatic Transmission Fluid for eCVTs, and they will deliver the same high performance in eCVTs as they do in traditional automatic transmissions.